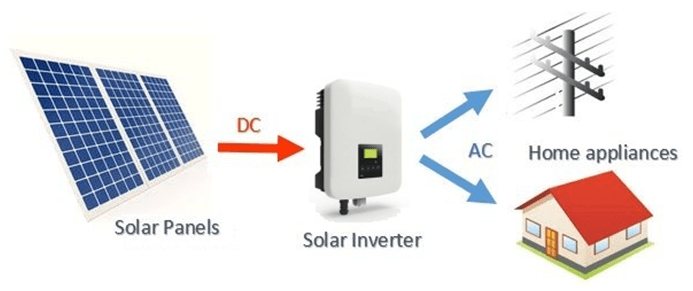

An inverter converts the DC power from the solar modules into conventional AC power and is the central component in a solar photovoltaic system. Without the inverter, the DC power generated from the solar modules would not be utilized by grid-connected homes or premises that typically require AC power to run the appliances.

The Inverter also alters the voltage levels. For example, it converts the voltage generated by a grid connected system, into standard AC voltage levels typically 230V (single phase), 440V (three phase) or even higher as per the load connected.

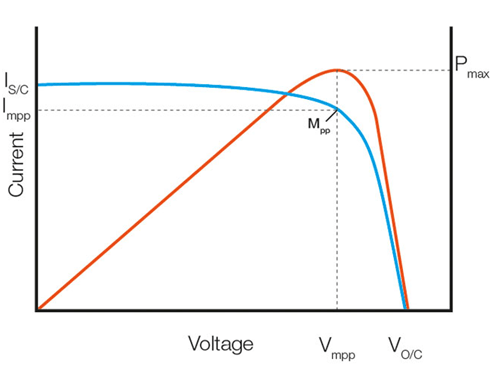

Modern solar inverters are equipped with maximum power point tracking (MPPT) circuit which constantly checks for the best operating voltage (Vmpp) and current (Impp) for the inverter to optimize power production. Its algorithm constantly searches for the optimum point on the IV curve for the system to operate at and holds the solar array at that voltage until environmental conditions change. Inverter MPPT algorithms are capable of sampling and changing the solar array voltage many times per second.

Every inverter has a voltage input window that indicates the maximum and minimum voltages that should be connected to the inverter.

The I-V curve for the solar module and the point of maximum power (MPPT) is shown in figure 2. The Inverter MPPT algorithm, tries to make sure that the solar array operates within the Inverter MPPT range, to generate maximum power and harvest more energy.

Power is the product of voltage and current and so the power vs voltage curve (represented by red line) shown in figure 2 can be generated from the measured voltage and current data. The power vs voltage curve shows the point at which the power is a maximum (Pmax). The corresponding maximum power point Mpp is shown on the I-V curve.

Loading the PV module such that the current is Impp and voltage is Vmpp will operate the PV module at the maximum power point (Mpp) and result in the maximum power generation.

Thus, a solar inverter primarily plays the following roles in a solar power system:

- Conversion of DC to AC power

- Maximization of energy production

- Ensuring safe system operations

- Improved grid assistance capabilities

- Efficient tracking of power output

Types of Solar Inverters

There are different types of Inverters that are available in the market. The Inverter types are classified as follows:

- String Inverters

- Central Inverters

- Micro Inverters

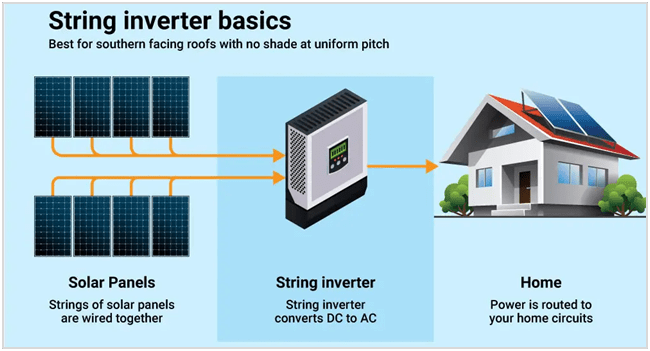

String Inverters

In String Inverters, a group of solar modules are connected in series, termed as strings. Several of the strings are combined and connected in parallel which are then fed as the Input to the Inverter where electricity is converted from DC to AC electricity.

A string inverter is typically capable of handling multiple strings of panels attached to it. String inverters are also called as On-grid inverters on the basis of their working methodology.

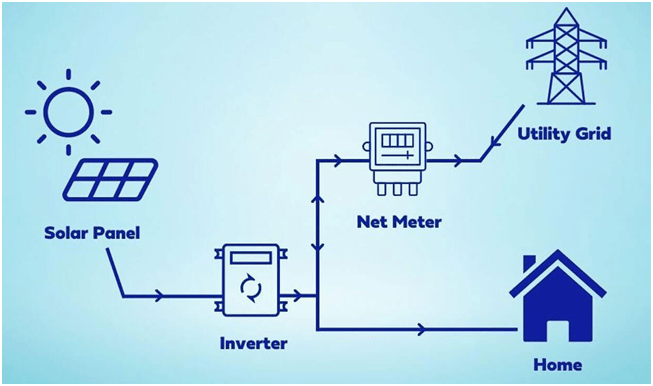

Grid Interactive or Grid Tied or On-Grid Solar Inverter

Grid interactive solar inverters are the most common type of solar inverters used for grid connected buildings. The DC power from the PV array system flows into the inverter during the day, and the output AC power flows either to loads in the house or out to the utility grid, in the absence of any connected load. Excess AC power is fed to grid by the inverter via a net meter connection and is bought by the local electricity distribution company, thus leading to significant reduction in electricity bill of the consumer.

The grid-tied or string inverter also necessarily comes with anti-islanding feature which protects the inverter from any kind of power outage or shutdown from grid side.

In such a scenario, the inverter shuts itself off instantly and stops feeding any electricity to either the house loads or the grid. This is done to safeguard maintenance workers fixing the breakdown at the grid side from sudden inflow of current risking their lives. It wakes up as soon as the grid is active and resumes its assigned functions.

Standards and Specifications

Inverters/PCU should comply with applicable IEC/equivalent BIS standards for efficiency measurements and environmental tests as per the following standard codes.

| Standards | Specifications |

| IEC 62109 or IS: 16221 | Safety of power converters for use in photovoltaic power systems. Safety compliance (Protection degree IP 65 or better for outdoor mounting, IP 54 or better for indoor mounting) |

| IS/IEC 61683 latest | Photovoltaic Systems – Power conditioners: Procedure for Measuring Efficiency (10%, 25%, 50%, 75% & 90-100% Loading Conditions) |

| IEC 60068-2 /IEC 62093 | Environmental Testing of PV System – Power Conditioners and Inverters. |

| IEC 62116:2014/ IS 16169 | Utility-interconnected photovoltaic inverters – Test procedure of islanding prevention measures. |

Applications

These are the most commonly used solar inverters, for both business and household purposes. They generally have a 25-year design life along with a 5-year warranty.

Today, string inverters are being manufactured by leading brands like Fronius, Delta, SMA, Growatt, Sungrow, Havells etc. In terms of system capacity, they range from as small as 1 KW and go through 5KW, 10KW, 25KW, 50KW, 100KW upto 250KW.

Their market prices (without taxes) are as follows – 1KW – Rs. 18000, 5KW – Rs. 32000, 10KW – Rs. 55000, 25KW – Rs. 85000 and so on.

Advantages of String Inverters

- The smaller size compared to Central Inverters – Thus, in place of a large central inverter for a 1MW project, four string inverters of size 250 KW can be connected in series so that in case of system breakdown, faults can be easily identified in individual inverters by partial shutdown without hampering power generation from rest of the inverters.

- Multiple MPPTs in string inverters offer flexibility in string sizing and designing.

- DC Wire run size can be limited which will result in a reduction in power transmission losses.

Limitations of String Inverters

- System performance is affected, in case of partial shading.

- Higher cost per watts compared to Central Inverter.

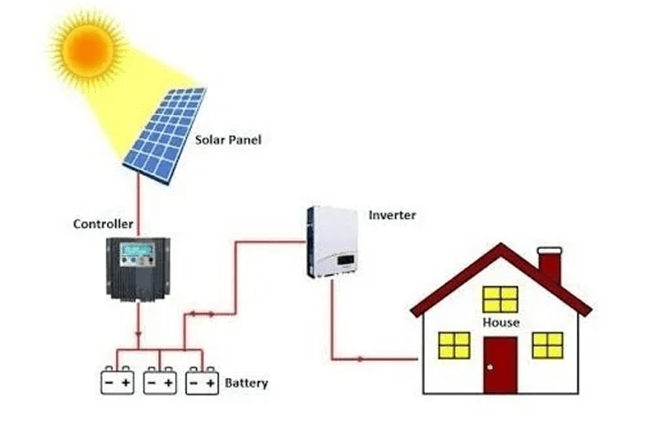

Off-Grid Inverters In contrast with On-grid inverters, Off-Grid or Standalone Inverter do not interact with the grid and use batteries to store the energy coming from solar array system and the grid. They use grid as their secondary source for charging the battery, solar array being the primary source. The battery provides DC electricity supply which is converted to AC current by the Off-grid inverter to run AC loads at homes.

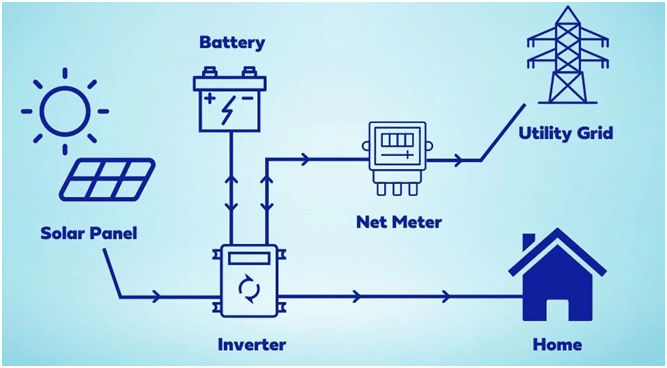

Hybrid Inverters

Then, there is also a new type of inverter where both the features of On-grid and Off-grid are combined which is called as Hybrid Inverter. A hybrid inverter performs just like a grid dependent inverter but has an added capability of converting AC power into DC power to charge standby storage batteries.

The battery bank can give uninterrupted power to essential loads during grid outage but does not operate loads on regular basis. The Inverter maintains the standby battery on “float” charge using both the DC power from the solar array and rectified AC power from the grid.

Applications:

Domestic and residential consumers such as hospitals, banks, schools, large residential societies, petrol pumps etc. wanting to have both storage and power saving options available to them due to their heavy energy consumption go for Hybrid Inverters.

Advantages of Hybrid Inverters

- A hybrid inverter can be an all-in-one solution to a domestic consumers’ power needs.

- It provides greater flexibility as a power system can be installed with only a utility grid connection, PV and AC loads, while a battery can be added a few years later when more capital is available.

- Hybrid inverters also avoid duplication of components when compared to discrete solar charge controllers and string inverters.

Limitations of Hybrid Inverters

- This type of installation provides limited uninterruptible capability along with solar power generation and is more costly and complicated to install than a pure grid connected systems.

- If a consumer wants to upgrade existing solar power system to include battery storage, choosing a hybrid inverter could complicate the situation, and a battery inverter might be more cost effective.

- This system can sometimes be less efficient for the system owners as the batteries add more cost and require constant charging.

All leading inverter companies in India like Schnider, Fronius, Jackson, Waaree, Havells etc. are providing off-grid inverters in the range of 1 KVA to 15 KVA costing approximately between INR 40000 to INR 2,80,000, respectively.

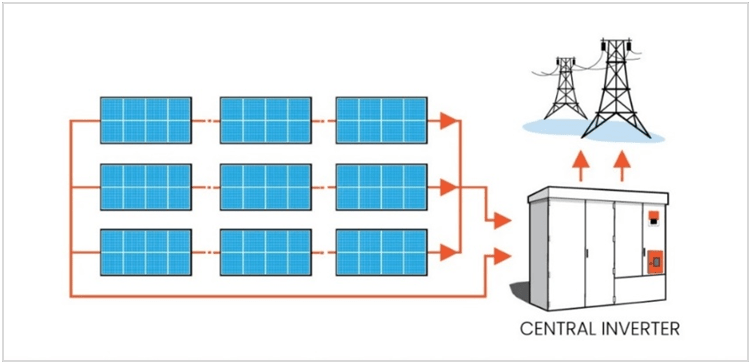

Central Inverters

Central Inverters are large, high-capacity Inverters that are at least 250 kW AC or more and are often coupled with a step-up transformer to boost the AC voltage so the energy can be transported longer distances. As such, these inverters are typically deployed in large utility scale ground mounted solar projects.

In case of a central inverter, all module strings are merged centrally. This is particularly useful when all PV modules are subject to similar conditions with respect to inclination and orientation.

Applications:

- Central inverters are usually used in the case of larger roof systems or free-space systems in the format of a control cabinet or as a station in container construction.

- Central inverters are generally used for large commercial installations, industrial facilities or utility-scale solar farms as central inverters support uniform and consistent production throughout.

Advantages of Central Inverters

- It is most suitable for utility scale solar pv projects.

- It is the most traditional inverter topology and is credible due to presence for long time and use in the market.

- System design and implementation is easy compared to other inverter technologies

- Lower cost compared to string inverters

- Maintenance and Troubleshooting is easy due to its high reliability.

Limitations of Central Inverters

- It incurs High DC wiring cost and Power Loss.

- It provides single MPPT for the entire PV system.

- Future expansion is difficult and has higher replacement cost.

- It has potential for a single point of failure even if a single panel is shaded or fails due to some other reason, it will affect the performance of the entire system.

- Monitoring can be done at array level only and not at module level.

- Requires use of heavy equipment’s during installation.

Some prominent companies involved in manufacturing Central Inverters are ABB, FIMER, DELTA, Hitachi etc.

A typical ABB 1000KW Central Inverter may cost around INR 25-27 Lakhs.

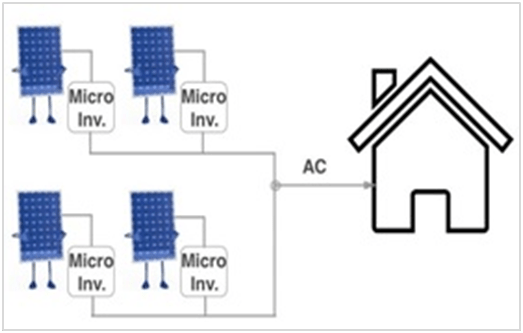

Micro-Inverters

A micro-inverter is a newer type of Inverter that is installed underneath solar module. It is designed to operate with a single PV module. Micro-inverters contrast with conventional string and central solar inverters, in which a single inverter is connected to multiple solar panels.

The micro-inverter converts the direct current output from each panel into alternating current thus replacing string and central inverters which handle very high voltage solar PV array. Its design allows parallel connection of multiple, independent units in a simpler way. Solar systems installed with micro inverters are very efficient compared to string inverters in installation areas where shading is prominent.

Applications

These are best suitable for residential and commercial arrangements wherein the solar panels face different directions, hence combating inefficiencies created due to shading. It is the perfect solution for installations where there is a disparity in the amount of sunlight received by individual solar panels.

Advantages of Micro-Inverters

- The main advantage is that they electrically isolate the panels from one another, so small amounts of shading, debris or snow lines on any one solar module, or even a complete module failure, do not disproportionately reduce the output of the entire array.

- Simplicity in system design, lower amperage wires, simplified stock management, and added safety are other advantages introduced with the micro-inverter solution.

- A single model can be used with a wide variety of panels, new panels can be added to an array at any time, and do not have to have the same rating as existing panels.

- Microinverters produce grid-matching AC power directly at the back of each solar panel. They need not handle thousands of volts of potential difference in the solar array.

- Microinverters have longer warranties, typically 15 to 25 years, compared with 5 or 10-year warranties that are more typical for string inverters.

Limitations of Micro-Inverters

- A micro-inverter incurs a higher initial equipment cost per peak watt than the equivalent power of a central inverter since each inverter needs to be installed adjacent to a panel.

- This also makes them harder to maintain and more costly to remove and replace.

- its scope is limited for residential and small commercial installations.

Some of the leading companies making microinverters are Enphase, SMA etc.

The price details of Enphase microinverters are tabled below.

| Installation size (in KW) | Approx. Price (Per Watt) |

| 1 to 5 | INR 14 – 20/- |

| 5 to 10 | INR 20 – 18/- |

| 10 to 25 | INR 18 – 17/- |

| 25 to 50 | INR 17 – 16/- |

| 50 to 100 | INR 16/- |

| 100 to 500 | INR 16 – 14/- |

Writeup by Mayank Mishra