1. Introduction: The Importance of Earthing

In the world of electrical systems, safety is of paramount importance. One crucial aspect of ensuring safety is earthing. Proper earthing protects both individuals and equipment from the dangers of electrical faults, such as short circuits and lightning strikes. By providing a low-resistance path for fault currents, earthing helps prevent electric shocks and reduces the risk of fires. Now let’s understand what is earthing then we know about types of earthing.

2. What Is Earthing?

Earthing, also known as grounding, refers to the process of connecting electrical equipment and installations to the Earth’s conductive surface. It involves establishing a direct connection between the electrical system and the ground, creating a safe pathway for excess electrical energy to dissipate harmlessly.

3. Why Is Earthing Necessary?

Earthing serves several important purposes in electrical systems:

- Safety: Earthing minimizes the risk of electric shocks by diverting fault currents away from people and objects.

- Equipment Protection: It helps prevent damage to electrical equipment and appliances by providing a low-resistance path for fault currents.

- Lightning Protection: Proper earthing reduces the risk of lightning strikes by providing a path for lightning currents to safely dissipate into the ground.

- Electromagnetic Interference (EMI) Reduction: Earthing helps mitigate electromagnetic interference, ensuring the proper functioning of sensitive electronic devices.

4. Types of Earthing

There are various types of earthing systems used in different situations. Each type has its own characteristics and suitability based on factors like soil resistivity and available space. The following are some commonly used types of earthing:

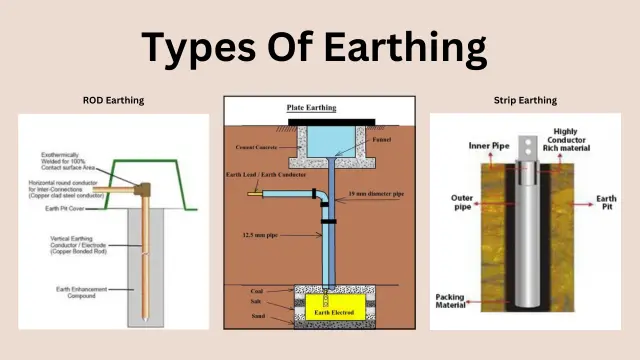

4.1. Plate Earthing

Plate earthing involves burying a metal plate, typically made of copper or galvanized iron, in the ground. The plate acts as an electrode and is connected to the electrical system. Plate earthing is commonly used in residential and small commercial buildings.

4.2. Pipe Earthing

Pipe earthing utilizes a metal pipe, such as a galvanized iron pipe or a copper pipe, as the electrode. The pipe is driven vertically into the ground, and the electrical system is connected to it. Pipe earthing is suitable for areas with high soil resistivity.

4.3. Rod Earthing

Rod earthing involves the use of a metal rod, usually made of copper or galvanized iron, driven vertically into the ground. The electrical system is connected to the rod. Rod earthing is effective in areas with low soil resistivity.

4.4. Strip Earthing

Strip earthing employs a metal strip, such as a copper strip or a galvanized iron strip, buried horizontally in a trench. The strip acts as the electrode and is connected to the electrical system. Strip earthing is commonly used in industrial and commercial settings.

4.5. Earthing through Water Pipe

In this method, the existing water pipe system is utilized as the earthing electrode. A separate connection is made from the electrical system to the water pipe. This type of earthing is commonly found in older buildings where metal water pipes are present.

4.6. Earthing with Earth Electrode

Earth electrode earthing involves the use of a specialized earth electrode, such as a copper-bonded steel electrode or a chemical electrode, that is specifically designed to provide low resistance and long-lasting earthing.

4.7. Chemical Earthing

Chemical earthing utilizes a chemical compound surrounding the electrode to enhance its conductivity and reduce soil resistivity. This type of earthing is beneficial in areas with high soil resistivity or corrosive soil conditions.

5. Factors to Consider When Choosing Different Types of Earthing Systems

When selecting an earthing system, several factors should be taken into account:

5.1. Soil Resistivity

Soil resistivity is a critical factor in determining the effectiveness of an earthing system. Different types of soil exhibit varying resistivity levels, which can affect the choice of earthing method.

5.2. Space Availability

The available space at the site influences the selection of the earthing system. Some methods, such as plate earthing, require larger surface areas, while others, like rod earthing, are more suitable for compact spaces.

5.3. Moisture Content

The moisture content of the soil affects its conductivity. Moist soil generally offers better conductivity, making it favorable for earthing systems.

5.4. Corrosion Resistance

Certain types of soil contain corrosive substances that can damage electrodes over time. It is essential to consider the corrosive nature of the soil and choose materials with appropriate corrosion resistance.

6. The Process of Earthing Installation

Proper installation of the earthing system ensures its effectiveness. The installation process typically involves the following steps:

6.1. Site Evaluation

Before installing the earthing system, a thorough evaluation of the site is necessary. Factors like soil resistivity, moisture content, and available space need to be assessed.

6.2. Selection of Earthing System

Based on the site evaluation, the most suitable type of earthing system is selected, considering factors such as soil resistivity, space availability, and corrosiveness of the soil.

6.3. Installation and Wiring

The chosen earthing system is installed according to the recommended guidelines and standards. Proper wiring ensures a secure connection between the electrical system and the earthing electrode.

6.4. Testing and Maintenance

After installation, testing is conducted to verify the effectiveness of the earthing system. Regular maintenance is also essential to ensure that the system remains functional and free from any faults or damages.

7. Advantages and Disadvantages of Different Types of Earthing

Each type of earthing has its own advantages and disadvantages. Plate earthing, for example, is easy to install but requires a large surface area. Rod earthing is suitable for low-resistivity soil but may be challenging to install in compact spaces. Understanding the pros and cons of each type helps in selecting the most appropriate earthing system for specific applications.

8. Conclusion

Earthing is a critical aspect of electrical system safety. By providing a safe pathway for fault currents, it protects individuals and equipment from the risks of electrical faults. Understanding the different types of earthing and their suitability in various scenarios is vital for ensuring optimal safety and performance.

FAQs (Frequently Asked Questions)

9.1. What is the purpose of earthing?

Earthing serves multiple purposes, including protecting individuals and equipment from electric shocks, preventing damage to electrical appliances, and reducing the risk of fires caused by electrical faults.

9.2. Can I install earthing myself?

While basic earthing systems can be installed by homeowners, it is recommended to consult a qualified electrician for more complex installations to ensure safety and compliance with electrical regulations.

9.3. How often should earthing be tested?

Earthing systems should be tested periodically to ensure their effectiveness. It is generally recommended to have the system tested at least once every few years or after any significant modifications to the electrical installation.

9.4. Is chemical earthing better than rod earthing?

The choice between chemical earthing and rod earthing depends on various factors such as soil resistivity, corrosiveness of the soil, and available space. Both methods have their advantages and suitability based on specific requirements.

9.5. Can I use multiple types of earthing in one system?

In certain cases, using multiple types of earthing methods in a single system may be necessary to optimize safety and performance. However, careful consideration and professional guidance are essential to ensure compatibility and proper functioning.