Electrical safety is very important. Plate earthing plays an important role in achieving this by providing a safe path for electrical current to flow into the ground in case of a fault or short circuit. When it comes to electricity, safety is the most important thing. Plate Earthing, a way to ground things that quietly save people and things, is one of the unseen stars in this world. This detailed guide goes into important details about plate earthing, including its core principles, components, advantages, installation process, maintenance strategies, and how it helps with following electrical safety rules.

Understanding Plate Earthing

Ensuring the safety of electrical systems is very important. A grounding method called plate earthing is very important for this because it lets unwanted electrical current flow safely into the earth during a fault or short circuit. This in-depth guide goes into great detail about plate earthing, describing its components and how it compares to other earthing methods.

The Real Meaning of Plate Earthing

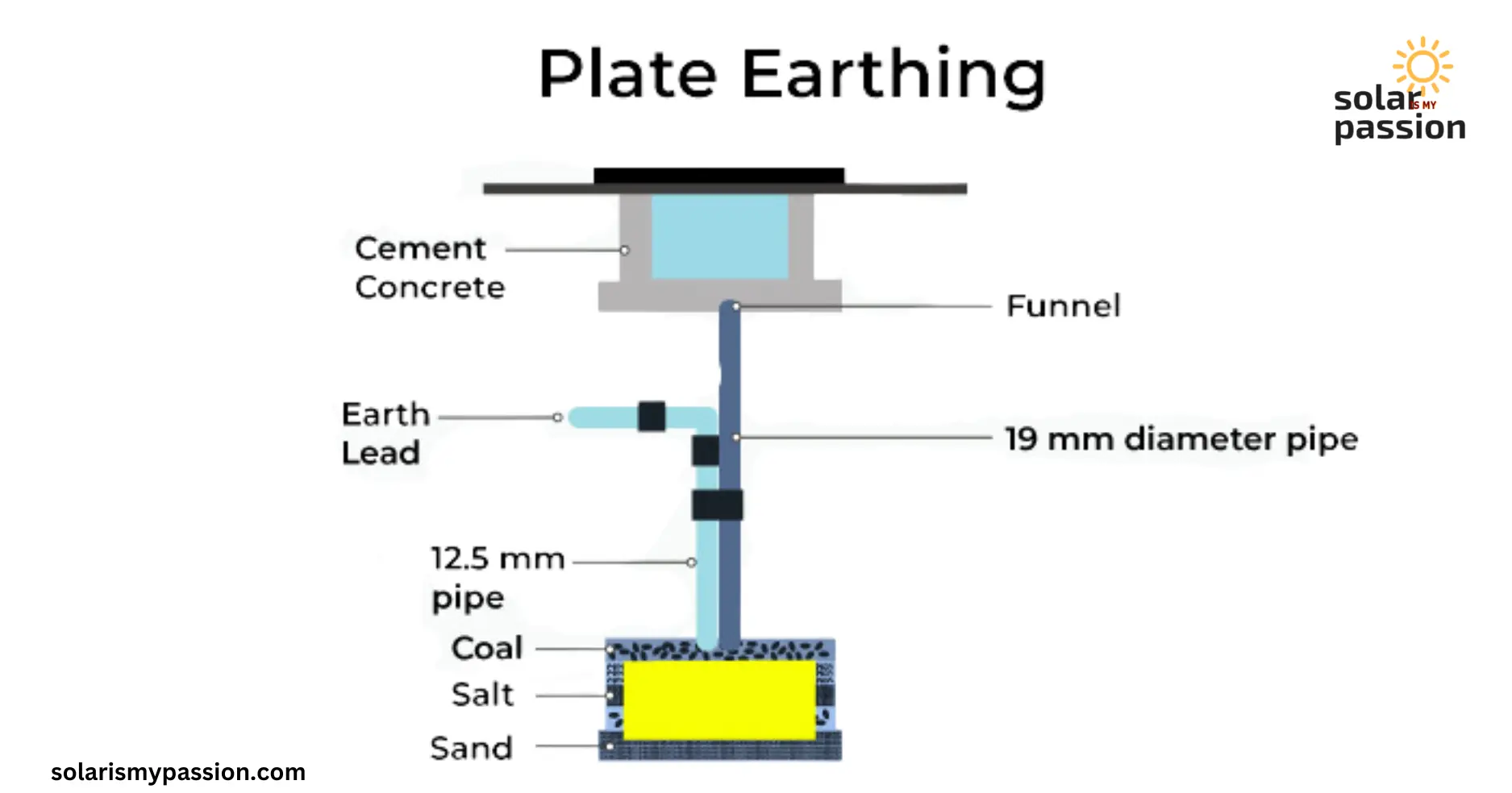

Plate Earthing is the process of sinking a metal plate of the right size (usually made of Copper, Galvanized Iron, or Steel) vertically into the ground. This plate acts as a big conductor, offering a low-resistance pathway for electrical current to flow safely into the ground in case of an electric problem.

Components of a Plate Earthing System

A plate earthing system is comprised of several key elements:

- The Plate: The heart of the system, this flat plate is crafted from a conductive material with good corrosion resistance. Its size is determined by factors like soil conditions and the amount of current the system needs to handle.

- The Electrode: The electrode term describes the plate itself and any additional conductors buried to enhance the earthing effectiveness. Essentially, it’s the entire underground network facilitating current flow.

- Backfill Material: In some cases, particularly when dealing with dry or poor soil conditions, conductive material like Coke Breeze is used to surround the plate. This backfill material improves the earthing efficiency by lowering the resistance between the plate and the surrounding soil.

- The Conductor: This important material link, typically a copper or aluminum wire, is securely attached to the plate. It acts as the bridge, carrying any fault current from the plate to the designated grounding point within the electrical system.

Alternative Earthing Methods

While plate earthing is a popular choice, it’s not the only contender in the earthing arena. there are also other types of earthing. Here’s a comparison with two other methods.

- Rod Earthing: This method utilizes a single metal rod driven deep into the ground. While space-efficient, it might not achieve the desired low resistance in all soil types.

- Strip Earthing: Here, a long, flat conductor is buried horizontally in trenches. This method is often used in substations where space permits a more extensive grounding network.

The Advantages of Plate Earthing

It is clear that plate earthing is the best way to keep electrical systems safe because it has many benefits. Let’s talk more about the advantages of plate earthing.

Enhanced Safety for Personnel and Equipment

- Fault Current Management: When there is a fault or short circuit, plate earthing lets the unwanted current easily flow into the ground with little resistance. This makes it much less likely that someone will get an electric shock if they come into touch with the broken equipment.

- Equipment Protection: By diverting dangerous fault currents away from electrical equipment, plate earthing safeguards valuable machinery and components from damage. This translates to reduced equipment downtime and replacement costs.

- Reduced Fire Risk: Electrical current that flows without being managed can cause things to get too hot and even start a fire. Plate earthing successfully lowers this risk by providing a safe path for fault currents, preventing them from igniting surrounding materials.

Superior Reliability and Durability

- Low Resistance, Guaranteed Safety: Plate earthing systems are designed to achieve a low and stable resistance between the plate and the ground. This ensures consistent and effective grounding, minimizing the chances of electrical problems.

- Corrosion Resistance: Copper plates are a popular choice for plate earthing, and offer excellent resistance to corrosion compared to rods used in rod earthing systems. This translates to a longer lifespan and reduced maintenance requirements for the earthing system.

- Adaptability to Varying Loads: The size of a plate can be adjusted to accommodate different electrical systems with varying current-carrying requirements. This allows for customization and ensures the system can handle the anticipated electrical load effectively.

Beyond Safety: Additional Benefits of Plate Earthing

- Cost-Effectiveness: While the initial installation cost of plate earthing systems might be slightly higher than some alternative methods, the long life, minimal maintenance requirements, and enhanced equipment protection contribute to significant cost savings in the long run.

- Scalability: Plate earthing systems are easy to change in size based on what the electrical system needs. These features make them good for many uses, from homes to big factories.

The next section of this guide will explore the installation process for plate earthing systems, providing a step-by-step breakdown to ensure a safe and effective grounding solution.

A Step-by-Step Guide to Plate Earthing Installation

While plate earthing has many advantages, proper installation is crucial for its effectiveness. This section provides a step-by-step guide to navigate the installation process, ensuring a safe and functional earthing system. However, it’s important to remember that electrical work can be dangerous. If you are not a qualified electrician, consulting a professional for installation is highly recommended.

Plan and Obtain Permits

Research and understand local building codes and electrical regulations regarding earring systems. Obtaining any necessary permits before commencing the installation is essential.

Gather Materials

Based on your chosen plate size, soil conditions, and electrical system requirements, acquire the following materials.

- Copper, galvanized iron, or steel plate (size determined by calculations or consulting an electrician)

- Copper or aluminum conductor wire (size based on current rating)

- Clamps and connectors for securing the conductor to the plate

- Conduit pipe (optional, for protecting the conductor underground)

- Backfill material (e.g., coke breeze) – especially for dry soil

- Excavation tools (shovel, pickaxe, etc.)

- Multimeter for earth resistance testing (essential for verifying effectiveness)

Location Selection

Choose a suitable location for the earthing pit. It should be.

- Away from buildings and structures (minimum distances specified in local codes).

- At a safe distance from underground utilities (consult utility maps to avoid accidental damage).

- In an area with good moisture content (consider seasonal variations).

Material Selection

The right plate size and material will depend on the local rules and the needs of the electrical system. You can choose the best materials by talking to a qualified electrician or referencing relevant electrical codes, such as the National Electrical Code (NEC) or the International Electrotechnical Commission (IEC).

Following Safety Standards

It’s important to adhere to safety regulations throughout the installation process. Here are some key points to consider.

- Always prioritize safety. If unsure about any aspect of the installation, consult a qualified electrician.

- Turn off the electrical power supply before working on the electrical system.

- Use appropriate personal protective equipment (PPE) like gloves and safety glasses.

- Ensure all connections are secure and meet electrical safety standards.

The Installing Process for Plate Earthing

- Excavation: Dig a pit with a depth sufficient to accommodate the chosen plate size (typically a minimum of 3 meters or 10 feet). Aim for a width that allows for comfortable maneuvering during plate placement.

- Plate Placement: Lower the plate carefully into the pit and ensure it’s positioned vertically.

- Conductor Connection: Securely connect the conductor to the plate using appropriate clamps and connectors. Ensure a good electrical connection.

- Conduit Protection (Optional): If desired, thread the conductor through a protective conduit pipe before lowering it into the pit. This provides additional mechanical protection for the conductor underground.

- Backfill Material: If using backfill material like Coke Breeze, carefully fill the space around the plate and conductor in the pit. Ensure the plate remains in an upright position.

- Topsoil Layer: Once the backfill material is in place, cover the top of the pit with the excavated topsoil, creating a level surface.

Connection and Testing

- Grounding Point Connection: Connect the other end of the wire to the grounding point that is marked on the main panel of the electrical system. An electrician should be the one to make this link.

- Earth Resistance Testing: Do not connect the electrical system to power. Use a multimeter with an earth resistance testing function to measure the resistance between the earthing plate and the earth. The measured value should be within the limits set by local laws (consult an electrician for specific values). A low resistance value indicated an effective earthing system.

Final Touches

- Labeling: Clearly label the location of the earthing pit for future reference. This can be done with a permanent marker on a nearby structure or a dedicated marker post.

- System Activation: Once testing is complete and all connections are verified, a qualified electrician can connect the system to the electrical power grid.

Specialized Tools and Equipment

While most of the installation process can be accomplished with basic excavation tools, a few specialized tools might be helpful.

- Earth Auger (Power Tool): This motorized tool can expedite the digging process, especially in hard or compacted soil.

- Earth Clamp: This specialized clamp simplifies the secure connection between the conductor and the plate.

Maintaining and Testing Your Plate Earthing System

A well-maintained plate earthing system is important for ensuring the continued safety and effectiveness of your electrical system. Like any good monitor, your plate earthing system needs to be checked on a regular basis to make sure it keeps watching out for electrical hazards. This section delves into the importance of maintenance, details specific procedures, and expires testing methods for best performance.

Importance of Regular Maintenance

Over time, various factors can affect the efficiency of a plate earthing system. Regular maintenance helps identify and address these problems they compromise safety. Here’s why maintenance is so important.

- Sustained Effectiveness: Regular inspections and testing ensure your earthing system maintains a low resistance path for fault current, safeguarding personnel and equipment.

- Early Detection of Issues: Maintenance helps identify problems like corrosion or loose connections early on, allowing for prompt repairs before they escalate into bigger issues.

- Compliance with Regulations: Many localities have regulations mandating periodic maintenance of earthing systems. Regular maintenance ensures you comply with these regulations.

Detailed Maintenance Procedures

Maintaining a plate earthing system involves a combination of visual inspections, testing, and addressing any identified deficiencies.

- Visual Inspection: Conduct a thorough visual inspection of the earthing pit and surrounding area. Look for signs of damage to the conductor, corrosion on the plate, or erosion of the topsoil layer.

- Soil Testing: Especially in areas prone to seasonal variations, periodic soil testing is recommended. This helps assess the moisture content and conductivity of the soil, as changes can affect the earthing system’s effectiveness.

- Frequency of Maintenance: The recommended frequency for maintenance can vary depending on local regulations, soil conditions, and the criticality of the electrical system. Generally, final visual inspection and biannual soil testing are a good starting point. Consult a qualified professional electrician for specific recommendations for your system.

Testing Methods

Several testing methods ensure your plate earthing system functions optimally:

- Earth Resistance Testing: This crucial test measures the electrical resistance between the earthing plate and the surrounding soil. A low resistance value indicates a good path for fault current. Local regulations often specify acceptable resistance values.

- Continuity Testing: This test verifies the integrity of the electrical connection between the plate and the grounding point within the electrical system. A faulty connection can compromise the effectiveness of the earthing system.

Maintenance Concerns

- Minor Issues: If minor issues like loose connections or surface rust are identified, a qualified electrician can address them promptly.

- Major Issues: In case of significant corrosion, extensive damage to the conductor, or consistently high earth resistance readings, consulting a qualified electrician for repairs or potential system replacement might be necessary.

NOTE: By implementing a regular maintenance schedule and utilizing the appropriate testing methods, you can ensure your plate earthing system remains a reliable monitoring system of electrical safety.

Common Issues and Troubleshooting for Plate Earthing Systems

Even the most careful monitor can face challenges. Plate earthing systems can have problems that make them less efficient, just like any other system. This section explores possible problems, their signs, and how to fix them so that your earthing system keeps working properly. But it’s important to keep in mind that working with electricity can be dangerous. If you’re not sure about any part of fixing, you should always consult a qualified electrician.

Identifying Main Problems

Multiple factors can possibly make a plate earthing method less effective.

- Corrosion: Over time, the plate and conductor can corrode, increasing the resistance and reducing the system’s ability to conduct fault current safely.

- Inadequate Soil Moisture: Dry soil conditions can decrease conductivity, making it harder for current to flow effectively through the earth.

- Improper Installation: Faulty installation practices, like using an undersized plate or neglecting backfill material in dry soil, can compromise the system’s effectiveness from the outset.

- Physical Damage: Accidental damage to the conductor or plate due to excavation work or environmental factors can disrupt the earthing path.

Symptoms that Your Earthing System Isn’t Working Right

An earthing system that isn’t working right might not always show clear signs, but here are some potential indicators to look out for.

- Tingling sensation on metal surfaces: This could indicate a buildup of stray current due to a faulty earthing system.

- Frequent tripping of circuit breakers: This might suggest the earthing system is not effectively handling fault currents.

- Burning smell near electrical equipment: This can be a sign of overheating due to malfunctioning earthing and potential electrical faults.

Problem Tips and Solutions

Here are some initial troubleshooting steps for common electrical issues.

- Corrosion: Regularly check the plate and conductor for signs of corrosion. Minor surface rust can be addressed with appropriate techniques by an electrician. However, extensive corrosion might necessitate plate or conductor replacement.

- Inadequate Soil Moisture: In places that get dry spells often, you might want to add additives that keep water in the soil around the earthing pit to make it more conductive. But you should always talk to an electrician before making changes to the earthing system.

- Physical Damage: If visible damage to the conductor or plate is identified, do not attempt repairs yourself. Contact an electrician to assess the situation and recommend repairs or replacements.

You can take an active role in maintaining your plate earthing system by learning about possible issues, their signs, and simple ways to fix them. Remember that it is very important to get help from a trained electrician when you are working with complicated problems or doing work on the electrical system itself.

Regulations and Standards for Plate Earthing

Plate earthing systems need to follow rules and regulations just like any other electrical device to make sure they are safe and work well. In this section, we’ll talk about why following the rules is important and some of the rules that apply to plate earthing.

Importance of Following Regulations and Standards

- Safety First: Electrical safety is a top priority for regulations and standards, which set base requirements for earthing systems. These standards make sure that the system can handle problem currents well and keep people and things safe.

- Consistent Performance: Standards provide a framework for designing and installing earthing systems that deliver reliable performance across various applications and environments.

- Compliance Verification: Following rules often means getting checks and permissions from the right people. That way, the method is sure to meet set safety standards.

Relevant Regulations and Standards

Plate earthing methods are guided by a number of rules and laws. Which ones you need will depend on where you live and how your electricity system works. Here are some well-known examples.

- National Electrical Code (NEC): Widely used in North America, the NEC provides comprehensive regulations for electrical installations, including earthing systems.

- International Electrotechnical Commission (IEC): This international organization publishes a series of standards related to electrical safety, including IEC 60038 which covers earthing practices.

- Local Building Codes: Many localities have their own building codes that establish specific requirements for earthing systems in their jurisdiction.

Responsibility of Compliance

Ultimately, the responsibility for ensuring compliance with regulations and standards falls on the owner or operator of the electrical system.

- Consulting with a qualified electrician: The best electrician can advise on the specific regulations applicable to your situation and ensure the design and installation of your plate earthing system adhere to relevant standards.

- Obtaining Permits: Depending on local regulations, permits might be required before installing a plate earthing system.

- Maintaining Documentation: Keeping records of the design, installation, and testing of your earthing system is crucial for demonstrating compliance during inspections.

In conclusion, plate earthlings play an important role in safeguarding the electrical system. By understanding its components, advantages, and proper installation procedure, you can ensure a safe and reliable electrical environment. Remember, when dealing with complex electrical systems, consulting a qualified electrician is always recommended.